1.4919

- 316H

- S 31609

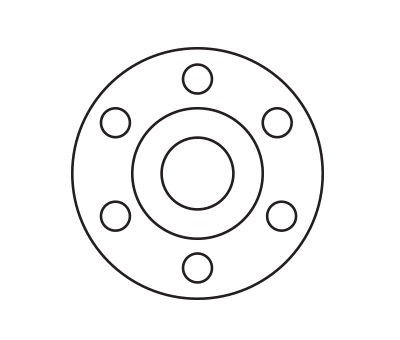

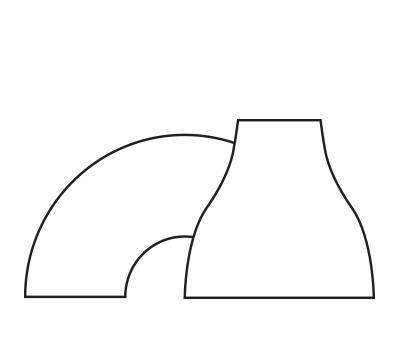

Austenitic chromium-nickel-molybdenum stainless steel in addition with nitrogen and boron. A High Carbon Version of 316 Austenitic Stainless Steel making it more suitable for elevated temperature service.Very good resistance to raised temperature. Application : Chemical and Petrochemical Processing – pressure vessels, tanks, heat exchangers, piping systems, flanges, fittings, valves, and pumps, power and nuclear plants.

Mechanical Properties

| Tensile strength: | 490-690 | N/mm² |

| Yield strength 0,2% : | 205 | ≥ N/mm² |

| Elongation: | 35 | ≥ % |

| Hardness HB30: | - | ≤ HB |

Chemical Composition

Carbon

C

0,04-0,08% max

Silicon

Si

0,75% max

Magnese

Mn

2% max

Phosphorus

P

0,045% max

Sulphur

S

0,015% max

Chromium

Cr

17,0-19,0%

Nickel

Ni

12,0-14,0% max

Heat Treatment

This alloy resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists corrosion in polluted marine conditions.

This alloy resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists corrosion in polluted marine conditions.

manual arc

It can be easily welded and processed by standard shop fabrication practices.

Marking

All material will be marked as follow:

- Manufacturer’s name

- Material grade

- Size

- Heat Number

Certification

Material will be delivered with certificate EN 10204 3.1