1.4410

- S32750

- Alloy 2507

- X2 CrNiMoN 25-7-4

UNS S32750 is a duplex stainless steel especially designed for service in aggressive chloride-containing environments. It has very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength. It is widely used in oil & gas, hydropower, pressure vessels, pulp & paper, structural components and chemical tankers.

Mechanical Properties

| Tensile strength: | 750 | N/mm² |

| Yield strength 0,2% : | 550 | ≥ N/mm² |

| Elongation: | 25 | ≥ % |

| Hardness HB30: | 270 | ≤ HB |

Chemical Composition

Carbon

C

0,03% max

Silicon

Si

0,80% max

Magnese

Mn

1,20% max

Phosphorus

P

0,035% max

Sulphur

S

0,020% max

Chromium

Cr

24-26% max

Nickel

Ni

6-8% max

Nitrogen

N

0,24-0,32% max

Heat Treatment

Solution annealing at 1100°C followed by water quenching

High resistance to stress corrosion cracking in halide containing environments.

• High resistance to pitting and crevice corrosion.

• High resistance to general corrosion.

• High mechanical strength.

• High resistance to erosion corrosion and corrosion fatigue.

Very good

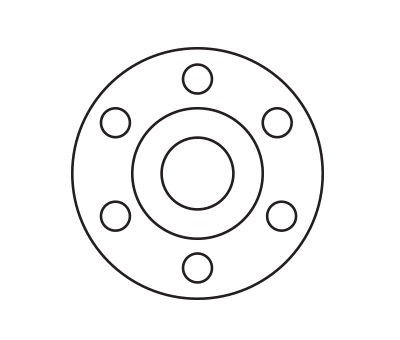

Marking

All material will be marked as follow:

- Manufacturer’s name

- Material grade

- Size

- Heat Number

Certification

Material will be delivered with certificate EN 10204 3.1

Other Duplex / Superduplex grades

| EURONORM/DIN | WERKSTOFF NR. | AISI | UNS | BRAND NAME |

|---|---|---|---|---|

| X2 CrNiMoN 25-7-4 | 1.4410 | F53 | S 32750 | URANUS 47N ® |

| X2 CrNiMoN 22-5-3 | 1.4462 | F51/F60 | S 31803/S32205 | URANUS 45N ® |

| X2 CrNiMoCuWN 25-7-4 | 1.4501 | F55 | S 32760 | ZERON 100 ® |

| X2 CrNiMoCuN 25-6-3 | 1.4507 | F61 | S 32550 |